Don Cowles is a full-time

knifemaker. Born in California, he has lived in Washington State,

Oklahoma, Illinois, Massachusetts, Venezuela, New Jersey, New

York, and currently resides in Royal Oak, Michigan.

Don's knife making career has been interrupted by a number of

temporary jobs. He has been an engineer, teacher, policeman,

paramedic, bartender, therapist, guitar repairman, winery manager,

and a technical writer, among other things. He made his first

knife in 1963, and a number of knives in the following decades. In

1995, he bought a Burr King belt grinder, and has never looked

back.

In the last few years, he has devoted much time to the craft of

making cutlery of his own design, focusing primarily on smaller

straight knives as elegant alternatives to folding knives. He is a

member of the Miniature Knifemakers Society, and the

American Knife and Tool Institute, contributes as a moderator

to online

knife discussion forums, and writes the occasional article for

knife magazines.

Don is an avid fly fisherman, an

accomplished singer and guitarist, and is active in his church. He

loves to talk knives, and share the experience and knowledge that

was so generously shared with him by others.

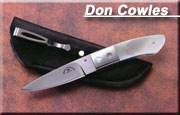

Don Cowles hand-makes knives of his

own design from the initial concept to the finished product. His

love of fine craftsmanship is apparent in his work. Although he

makes some knives to similar patterns, each is a unique creation;

a true one-of-a-kind offering. He is always experimenting with new

designs, materials, and techniques, so his knives are constantly

evolving.

Artistic Philosophy ...

Don insists on using his own hands for each operation involved,

without the use of fixtures or jigs or apprentices, although he

made an exception when he helped his grandson craft a blade. The

workmanship of Don's knives is guaranteed for life. He has a

well-equipped shop, but virtually all of the effort expended in

the making of a knife is hand work. In this way, he develops a

measure of intimacy with the materials and processes involved that

allows him to deeply understand the way things are coming

together, and to compensate for things like variations in natural

materials.

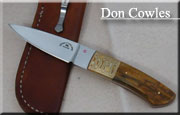

The Method ...

Starting

with bar stock of the best available knife steels, he grinds,

polishes, and heat treats his own blades. Bolsters and handle

materials are then attached and shaped by hand, of substances both

ordinary and exotic. He takes great pleasure in watching the

metamorphosis occur from raw materials to finished tools that are

both useful and attractive. Starting

with bar stock of the best available knife steels, he grinds,

polishes, and heat treats his own blades. Bolsters and handle

materials are then attached and shaped by hand, of substances both

ordinary and exotic. He takes great pleasure in watching the

metamorphosis occur from raw materials to finished tools that are

both useful and attractive.

He does some limited scrimshaw (and makes his own scrimshaw tools)

and engraving, and hand-stitches top quality sheaths that are

custom-fitted to each knife. Customer input is welcome on material

selection and design, within the framework of what he does best.

The Style

...

Here's Don's take

on what he makes:

"My gentlemen's straight knives

are designed as elegant alternatives to folding knives. I use

ATS34, BG42, 440C, CPM S30V, CPM 154, and RWL 34, as well as

stainless and carbon Damascus in a variety of patterns from

Bertie Rietveld, Jerry Rados, Daryl Meier, Robert Eggerling,

George Werth, Mike Norris, and Devin Thomas. Finishes for

non-Damascus pieces are usually hand rubbed.

Bolsters are 416 stainless steel,

or mokume gane from a number of different makers. Pins are 14K

gold. The signature ruby in the ricasso is set in 18K gold.

Handles are usually crafted from fine natural materials such as

mother of pearl and the fossil ivories, as well as rare woods,

although some pieces intended for rigorous use have been fitted

with carbon fiber or Micarta™.

Blade and handle shapes were

conceived with consideration for size, comfort, function, and

appearance. All are full-tang design, and even those knives with

Damascus blades are ground from a single piece of bar stock; no

welds are made to lower-grade steels to reduce material costs.

Tangs are tapered to reduce weight, as well as to improve

appearance.

A few words on the sheaths that

accompany my straight pocket knives: the concept is to provide a

secure method of holding the knife that keeps it readily

available, as well an attractive look that is in keeping with

the appearance of the knife itself.

Although the particular

combination of features on my sheaths is unique to me, each of

the "ideas" came from somewhere else. For example, I use a rare

earth magnet to help retain the blade in the sheath; an idea I

borrowed from Bud Nealy (and for which I thanked him a couple of

years ago), who uses them in his Kydex sheaths.

The clips come from Matt Conable

of William Henry Knives, who uses them on slip-cases for his

folders. I was told that Matt got the idea for the clip from a

sheath intended for pocket-carry of a pen. There is nothing new

under the sun after all, but there is much to be said for

availing one's self of the wisdom and experience of those who

have gone before.

To keep the inside of the clip

and the magnet from scratching the knife, I line the sheath with

soft goatskin. The hand-stitched exterior is made of exotic

leather or cowhide. Exotics include ostrich, crocodile, lizard,

frog skin, and sharkskin.

The clip allows the knife to be

attached to the inside of a trouser pocket in much the same way

that many folders are carried. I have developed a preference for

clipping it to the inside of my shirt pocket where it is just as

accessible as a pen or pencil.

The whole package is designed to

fit nicely in a pocket, yet still provide enough useful blade

and handle to slice a bagel or open a carton - they are, after

all, tools- and, at the same time, present an elegant and

non-threatening appearance. There is no reason why tools can't

have some class."

|